Our efficient and effective solutions always consider human and technical aspects; they are tailored to your needs, and are practical and implemented in a way which minimises disruption to your business. We transfer our experience and methodologies to you so that improvements endure. We pride ourselves in providing you different options for improvement so that you can decide exactly how to secure the bottom line and improve your return on investment.

We select the right blend of tools & techniques in order to complete your consulting requirements. Our methodologies, tools & techniques include: RCM, TPM, 5s, Six Sigma and Lean so that we can deliver the best solutions for your business.

Consulting Services |

Modelling Services |

Maintenance Auditing

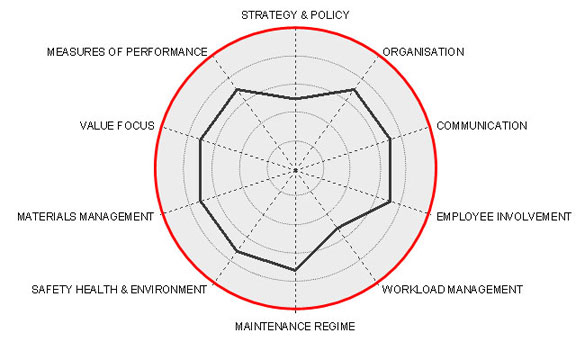

Our World Class Wheel is based on the ten of pillars of the EFQM business excellence model which have been interpreted for an operations / maintenance context. It is completed by a combination of structured interviews, data analysis, observations and plant visits. Full coverage is provided in a limited time and the output is an actionable improvement plan.

Maintenance Benchmarking

Our benchmarking database has been built up from a combination of 15 years of consulting experience across a range of industries and from publicly available information. This information includes:

|

|

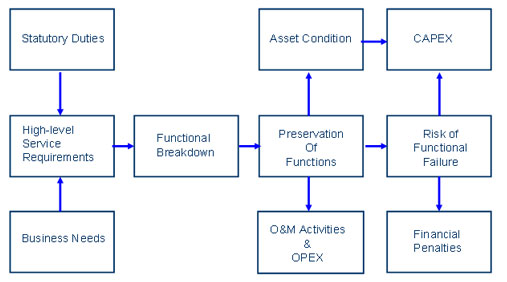

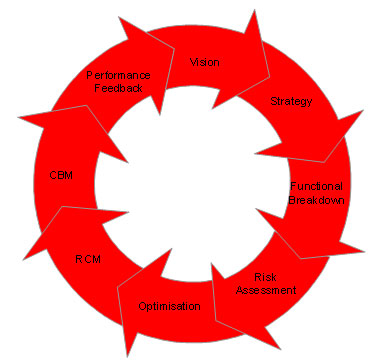

Maintenance Strategy Development

Our methodology takes into account the needs of all stakeholders. It is designed to prioritise capital and revenue activities making full use of existing data. Previous work is taken into account and local knowledge is used. The strategy ensures that resource-hungry techniques such as Reliability Centred Maintenance are focused on most needy areas.

Organisational Development

The maintenance organisation needs to be structured, staffed and skilled in the right way in order to deliver the maintenance strategy. We recognise that no single organisation model fits all situations so our recommendations will be tailored to your needs. Our holistic approach considers:

- Safe system of work

- Coverage of 1st, 2nd and 3rd line activities including working patterns, staff numbers, locations, skills

and competencies - Desirable level of out-sourcing

- Planning responsibility

- Preservation of standards and equipment integrity

- Asset care provision and flexibility with production staff

- Multi-disciplined engineering, supervisors and technicians

- Coverage of key interfaces with other company departments such as production, health & safety, projects, etc

- Computer and management systems

- Routine meetings and reports

- Performance management and continuous improvement

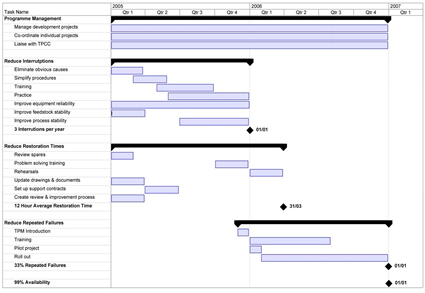

Performance Improvement

Reliability Improvement

Lean manufacturing and the trend towards producing more for less means that high reliability is more important than ever. Our reliability improvement methodology includes not only tried and tested root cause analysis techniques but also proper coding and feedback from maintenance work and the human factors necessary to ensure that the right behaviours are adopted by operations and maintenance staff. Project management techniques ensure that the reliability improvement activity delivers the required benefits on time and on cost.

Resilience Studies

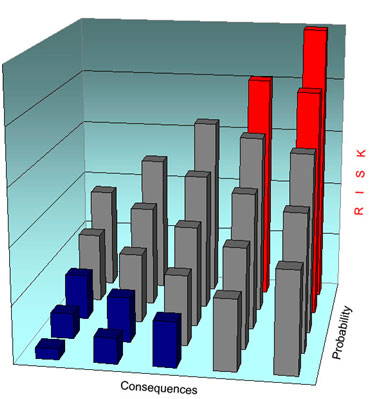

Our Red Alert resilience studies consider both probability & consequences of equipment failure in order to establish where an organisation may be ‘sailing close to the wind’ and running high operational risks. Recorded data together with the experience of front-line operations and maintenance personnel is used in order to gain a full picture. Consideration is then given to how these risks might be mitigated in the most cost-effective manner.

Asset Management Strategy Development

Our risk-based methodology is used to prioritise operating and capital expense activities. It is fully compliant with PAS55 / ISO 55000 requirements. Maximum use is made of existing data collected for other purposes and local knowledge of staff and key service providers. Recognising the expertise of our clients, we like to build on previous work instead of starting with a blank sheet of paper. Our approach focuses resource-hungry techniques such as life cycle modelling, scenario development and RCM on most needy areas instead of having a blanket approach.